13 Common Faults of Sand Washing Machine and Solutions

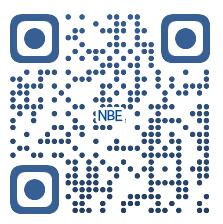

The sand washing machine is one of the washing equipment especially designed for Crusher and natural sand. In general, there are two kinds of the Crusher: spiral sand washing machine and wheel type sand washing machine.

Sand washing machines and their working sites

The sand washing machine can be widely used in the industries such as sand and aggregate plant, building materials, chemical engineering, high way, railway, water conservancy, and hydropower.

It can remove the impurities that covered in the surface of sand and aggregate and destroy the vapor layer wrapped around the sand particles, so as to high-efficiently clean and dry the sand and aggregate.

During the operation process, users will inevitably encounter a variety of faults. Fote Heavy Machinery shares some solutions to the common faults of the sand washing machine, hoping you can get help.

1. The sand product contains impurities

A. The water supply is insufficient.

B. The raw sand supply is excessive.

During the sand washing process, the flush pipe should be opened first, then the raw sand is sent into the sand washing machine.

The water supply should be moderate to keep clean of sand and to prevent sand from overflowing.

The raw sand supply should be uniform, thus guaranteeing the quality of the sand product.

2. The lower proportion of sand product or sand leakage

A. The sand washing screen is damaged.

B. The bolts of the sand washing screen are broken off.

A. Check, maintain, or even replace the sand washing screen.

B. Fasten the bolts of the sand washing screen.

3. The bearing is overheated

A. The lubricating grease is mixed with impurities.

B. The lubricating grease is used incorrectly.

C. The bearing is damaged.

A. Change for a better lubricating grease.

B. The lubricating grease should be added moderately.

C. Replace the bearings.

4. Water is splashed during the washing process

A. The speed of spiral washer is over fast.

B. The horizontal axis of the spiral disk is not fixed well.

A. Adjust the speed of the spiral sand washing machine.

B. Fix the horizontal axis of the spiral disk properly.

5. The discharging port is locked

It is probably caused by the too-small sand particles and too much raw sand supply, which results in the lockage of discharging port.

Stop feeding and open all discharging ports first to avoid the lockage. Only after cleaning the sand washing machine with clean water, can the further operation be carried out.